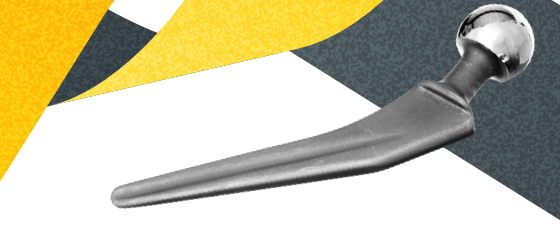

Extending Life & Reducing Weight

The premise behind our unique PEO metal coating is simple. It’s the science behind it that’s complex.

Our coatings offer two fundamental benefits:

- They extend the life of magnesium, aluminium and titanium components through a range of key characteristics unique to PEO. Our coatings are proven to be far superior to competing coatings such as anodising and thermal sprays.

- These improved performance characteristics facilitate the reduction in weight of a component and the wider use of light alloys in multiple industries.