PEO technology used on James Webb Space Telescope

Keronite, the world leader in Plasma Electrolytic Oxidation (PEO) technology, can today announce the company developed a life-increasing surface coating, by order of NASA, for the James Webb Space Telescope (JWST).

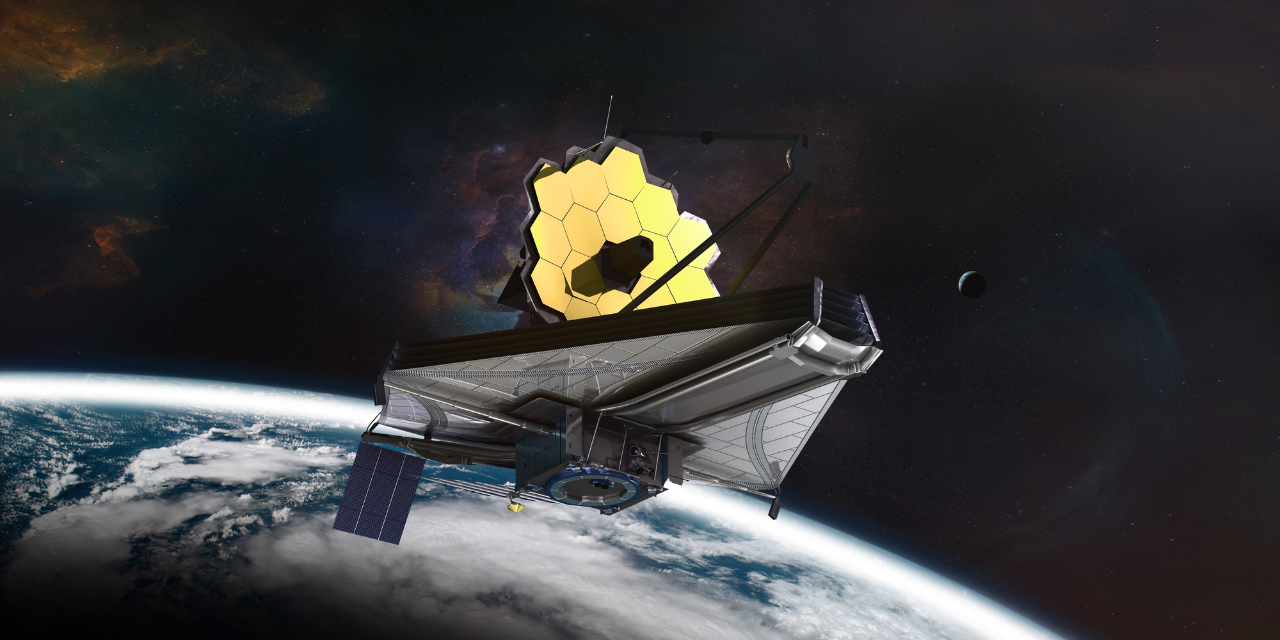

The JWST is the largest and most complex space telescope ever built and launched into space. NASA aims to revolutionise our study of distant galaxies, exoplanets and the formation of the first stars in our universe.

It is able to view stars and galaxies that are millions of years old from infrared capabilities provided by NIRSpec (Near Infrared Spectrograph), one of the primary science instruments onboard the JWST.

In order for NIRSpec to function in space, it needed protection against cold welding, extreme fretting wear and other factors. Cold welding is the process of two metals adhering to one another in a vacuum environment, creating potential complications for mechanical devices aboard the telescope such as the NIRSpec.

Keronite’s PEO technology was chosen as the coating technology for NIRSpec after extensive mechanical and thermal testing. PEO allowed for the coating of the complex structural parts of the NIRSpec whilst simultaneously protecting it from cold welding, extreme temperatures and fretting wear.

Keronite’s PEO technology is continuing to be adopted in the field of space technology. It was used as part of the BepiColombo satellite mission and it was recently featured in the UK Space Agency blog for a new coating enhancing optical performance.

To discover how Keronite’s scientists developed a solution against cold-welding for JWST, download the white paper below. If you would like to get in touch or hear more about our story as part of the JWST or information surrounding the PEO process, contact us today.