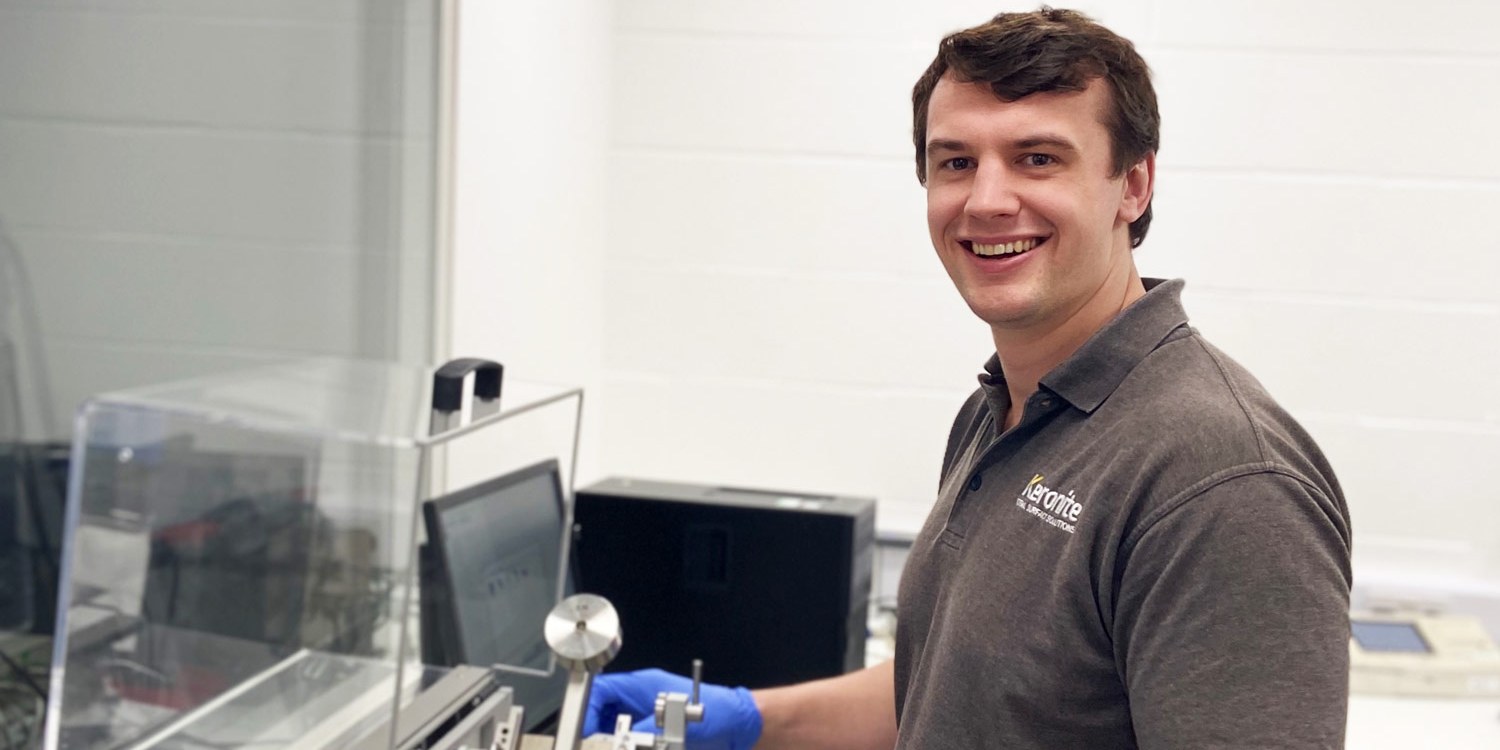

The Keronite approach to research and development: an interview with Sam Troughton

As the rate of technology change accelerates, remaining at the forefront of any field requires a unique mix of clever R&D direction and the brightest minds in the business.

The world’s most advanced coating for light alloys, plasma electrolytic oxidation (PEO), is continuing to provide fruitful results from lab experimentation. In a recent paper, Keronite worked closely with their partners at Cambridge University to investigate the use of suspended particles within PEO electrolytes.

We sat down with Sam Troughton, a key member of the project and a key figure of Keronite’s Applications Engineering team, to learn more about the project and Keronite’s agenda for research in the future.

Bringing together the brightest minds

Sam has been a full-time member of Keronite’s applications engineering team since October 2018. He joined having completed his Keronite-sponsored PhD in materials science, with a particular focus on plasma electrolytic oxidation.

Initially a keen physicist, Sam was a star pupil studying an integrated masters Natural Sciences degree at Cambridge. He won the coveted Goldsmiths’ prize and medal in his final year, by which point Sam was specialising in materials science. “As much as I like physics, the tangibility of materials science and the potential to put that to commercial use really drew me towards it”, Sam comments.

At Cambridge’s esteemed materials science and metallurgy department, Sam spent four years working on his PhD project. His then professor, Bill Clyne, is a member of Keronite’s technology advisory board. Working with Bill, Sam spent four years researching the fundamental processes of plasma electrolytic oxidation, with the project backed by Keronite. In 2018, Sam was awarded with his doctorate – but his ambition and drive to achieve real customer results made his decision to join Keronite an easy one.

Identifying research and development opportunities

In 2018, Sam joined Keronite’s applications engineering team full time. Keronite’s team split their time between customer-focused R&D, where Keronite’s team design bespoke-to-application coatings that uniquely improve the performance of components, and purer R&D projects. Sam noted that the team is working hard at the moment to achieve a corrosion-resistant coating for a magnesium alloy deployed in an aerospace application. Breakthroughs in this project could drastically transform the use of Mg in the industry.

Equally, Sam’s role also considers how the technology can continue to improve beyond its current world-class standards. In recent years, Keronite has made technology breakthroughs that enable PEO to be deployed inexpensively and on far larger components – making the advanced coating one of the most easily commercially deploying advanced coatings available.

Sam is embracing his move from the Cambridge laboratories to the fast-paced commercial life at Keronite. “I’ve recently started working on an MBA”, Sam said, where he hopes to combine his exceptional academic-nous with a mixture of managerial and commercial skills.

The research agenda

Sam was gracious enough to outline what he sees as key developments being made by Keronite to PEO coatings. Magnesium, in particular, is a material that Sam sees huge potential in, especially in applications where it was previously considered unsuitable, where corrosion is a key challenge.

Perfecting the wear qualities of these alloys is of particular interest because they’re among the lightest available. Ensuring they are suitably resilient could open a new range of possibilities in various sectors.

Another early-stage project exciting Sam concerns creating a “brush-on” variant of Keronite’s coatings. Currently, PEO coatings need to be applied in a specialist tank to ensure consistent coverage and full transference of resistive qualities.

“Any prospective brush-on PEO would require a more concentrated electrolyte than the existing technology, but would enable far more straightforward coating of small-area components,” Sam tells us. This would be especially useful for coating new or replacement parts in industries like aviation, saving energy and, crucially, time.

What’s next for Keronite

As one of the success stories of Keronite’s research partnership, Sam will continue to be a big asset for the company in the coming years.

However, he is just one of a number of specialists Keronite have recruited thanks to their relationship with the University of Cambridge and other institutions at the forefront of materials science. Nurturing talent in this way is helping the company to rapidly develop coatings with unprecedented levels of performance.

It’s an exciting time to be at Keronite

Keronite’s applications engineering team is at the heart of the company’s strategy. They are committed to continuing to lead the way in the development of PEO technology, as evidenced by the opening of their multi-million pound technology centre – the first of its type anywhere in the world.

Sam and his team are leading the charge. Keronite are determined to keep recruiting the very best talent in the sphere of material science.

To learn more about Keronite’s technology, download our free guide to Plasma Electrolytic Oxidation or take a look at our technical resources.